|

|

|

|

Understanding Extrusion of Plastics |

||||||||||||||||||||||||

|

Home Archives of Articles by Prabodh C. Bolur Energy Consumption in IM Machine A Guide to Injection Moulding of Plastics Introduction Answers to YOUR Questions Useful Links Author PlastIndia Photos Millineum's MoldFlow User Meet Contact Author Contact Publisher |

EXTRUSION plays a prominent part on the plastics industry. Extrusion, unlike moulding, is a continuous process, and can be adapted to produce a wide variety of finished or semi-finished products, including pipe, profile, sheet, film and covered wire. EXTRUSION PLANT

MATERIAL - MONOMERS, POLYMERS AND POLYMERISATION Polymers are large molecules built up by repetition of a very limited number of smaller molecules known as monomers. The process of joining the monomers to build up larger molecules is known as polymerisation. Many polymers occur naturally:

Different Polymers can be prepared synthetically following monomers are polymerised to produce their polymers

Plastics are usually polymers but polymers need not be plastics. Polymers are compounded with additives to improve their processibility.

Plastics material can be classified in two groups. Thermoplastics and Thermosetting plastics:

Plastics materials are most commonly processed in a viscous molten state which allows them to be shaped and moulded flow. Plastics material will only flow in the viscous molten state under the influence of heat and pressure.

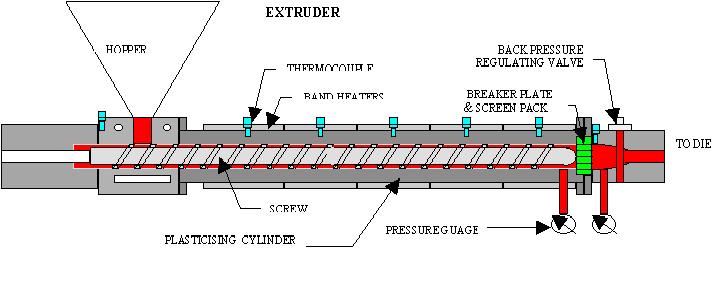

EXTRUDER In order to produce satisfactory extrudate it is necessary to apply heat to the granules in order to soften them and make the resulting melt capable of flow under some pressure. This is carried out rotated in the barrel by means of gear box and variable screw drive or Eddy current motor. Therefore the screw barrel has following functions:

In order to make each function as effective as possible it is normal practice to divide the screw into 3 zones:

The function of the feed zone is to collect granules from the feed hopper and transport (pump) them up the screw channel. At the same time the granules should begin to heatup and compact and build up pressure as they advance towards screw tip (die end). For efficient pumping the granules must not be allowed to lie in the screw channel. They must therefore show high degree of slippage on the screw channel surface and a low degree of slippage on the barrel. The maximum delivery of granules by the feed section may be achieved by:

With many polymers, such as polyethylene, it is found that the friction of polymer to metal increases with temperature upto about 120 degrees C. For optimum pumping we should therefore in theory try to have a cold screw in feed zone and hot barrel. In practice it is found that screw cooling reduces output. This is due to other effects occurring further down the screw. As the material goes from feed zone to melt zone there is an increase in the screw root diameter. This results in the decrease in the volume of space enclosed by the thread and the surface of the root in one complete turn of the screw. Granules melting should occur around the compression zone. The compression zone or Transition zone could be of two type.

The screw with sudden transition are required for plastic material with a narrow melting range such as nylon and screws with gradual transition are material with wide melting range COMPRESSION RATIO The ratio of the volume of the first turns of the channel of the screw (at hopper end) to the volume of the last turn of the channel (at the die end) is known as the compression ratio. This ratio usually between 1.5:1 to 4:1 depending upon the material.

In the melt zone (melting zone) the polymer melt is brought to the correct consistency and pressure required for extrusion. The melt should be pumped to the die at a constant rate, consistency and pressure. These properties may vary from point to point but when measured to a particular point should not change with time. Higher melt pressure is required in the metering zone in order to mix melt to give it constant properties through out hence obtain smooth extrudate. This pressure is generated by (a) restriction to flow in the melt zone and (b) restriction in the die head, (c) increase in melt viscosity. The restriction to flow in the metering zone is increased by

BREAKER PLATE At the end of the melt zone, there is often a breaker plate fixed between the barrel and die adapter. The thickness of breaker plate is slightly more than the two recesses (steps) cut in the barrel and the die head Breaker plate has following important functions:

To make these functions more effective it may be necessary to interpose stainless steel wire mesh screens between the breaker plate and screw. L/D RATIO The screw should have a sufficient length and diameter inorder to accommodate the feed, compression and melt zones so that the melt is in the correct state when it enters the die. Screw dimensions such as helix angle, channel depth and width are all significant. MELT TEMPERATURE CONTROL In order to melt the granules, heat is generated either internally by friction or by applying external heat from heaters wrapped around the barrel. It is necessary to control the heat supply because if the material becomes too hot it may decompose, degrade for become too fluid. If too cold it will be insufficiently plasticized, variations in temperature will also cause variations in flow rate. To prevent the over heating of the barrel through which cooling water or forced draught air may be circulated.

OUTPUT OF THE EXTRUDER It depends on (a) screw dimensions (b) die dimensions (c) screw rpm The following factors will increase output (1) increase of screw speed (2) increase of screw diameter (3) the helix angle up to a maximum about 30 degrees (4) an increase in die diameter When molten polymer emerges from a die many of its molecules will have been oriented in a direction parallel to the axis of the die orifice. When no longer constrained by die wall the molecules tend to recoil causing a contraction in the direction of extrusion and expansion in the iron section of the extrudate. This phenomenon is known as die swell. For this reason extrudate, unless hauled off at a greater rate then they are extruded show greater cross sections than those of the corresponding die orifice. DIES : (1) It is the die which determines the shape of an extrudate. Thermoplastic polymer molecules consist of long chains which tend to take up a randomly coiled configuration whenever possible. When such materials flow or forced through a die, the molecules become partially straightened or oriented. (2) When molten polymer emerges from a die many of its molecule will have been oriented in a direction parallel to the axis of the die orifice. When no longer constrained in the direction of extrusion and expansion in the iron section of the extrudate. This phenomenon is known as die swell. (3) For this reason extrudate, unless hauled off at a greater rate than they are extrudate show greater cross sections than those of corresponding die orifice. (4) under normal circumstances die swell may be reduced by the following:

(5) To get square cross section the shape of the die will be

(6) When a polymer melt flows through a tube the rate of flow is much greater in the center of the tube than near the walls. In fect there is no flow at the walls. (7) If we assume semicircle distribution of velocities in a given plane then the volumetric flow rate is less than half in the smaller tube than that of the larger tube.

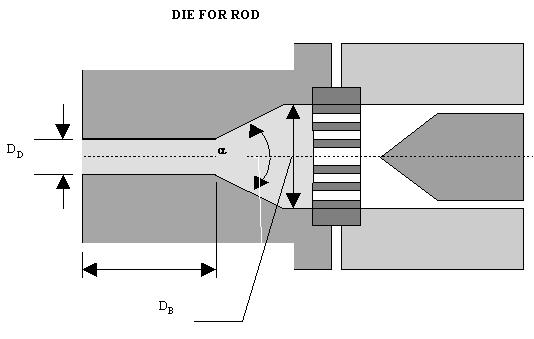

DIE FOR ROD: Because of the breaker plate the pressure in the melt on the barrel side of the breaker plate is greater than the pressure on the die size. At the die outlet the pressure is zero. It is however , important to have a sufficiently high pressure in the die so that the melt is consolidated after having been strained through the breaker plate and before emerging from the die. This is achieved by designing restrictions into the die, therefore ratio DD / DB should be less than half. The restriction to flow can be increased by increasing the die land. The rods can be made from different thermoplastics. Nylon gives a low viscosity melt under normal operating conditions and rigid PVC gives a high viscosity melt. The more viscous the melt the smaller is the lead-in angle will not be necessary than when extruding rigid PVC rod.

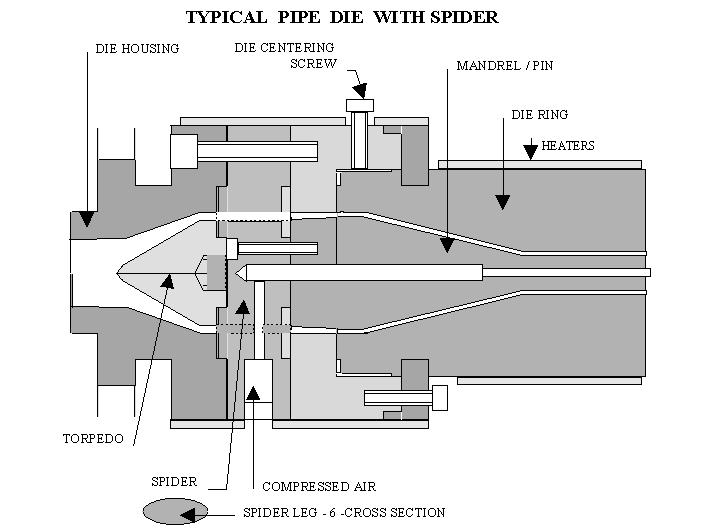

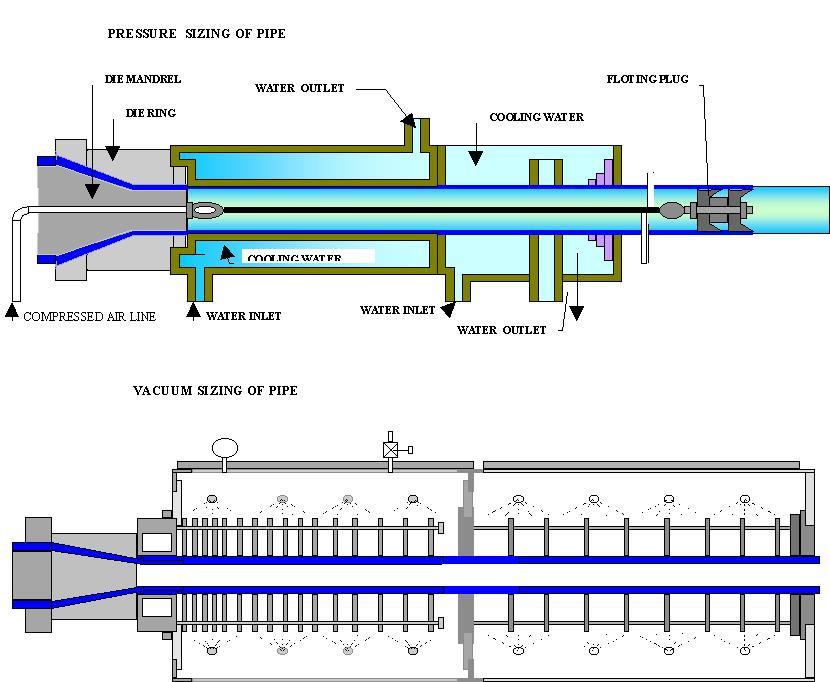

Dies for tubes or pipes If we ignore die swell, drawing down and any inflation after extrusion we can say that the diameter of the outer die ring orifice and the internal tube diameter by the diameter of the mandrel. In order to make mandrel and outer die ring orifice concentric, centering screws are provided to adjust the mandrel position. Unless such a facility is provided there is a danger that the product will have an eccentric cross section. The mandrel is held in position by a spider. The spider legs have a cross section to facilitate flow. It is common to drill a hole from one of the spider legs connecting an air supply to the air hole down the mandrel. This provision of compressed air allows the tube to be inflated to the internal diameter of the sizing die. When this technique is used the following factors will determine the internal diameter of the tube :

In order to provide a smooth glossy extrudate the die head is heated usually with some form of resistance heater attached to the surface of the die head body. A cold die would also cause the polymer melt to freeze, blocking the outlet from the extrudate. Since over heating can cause such problem as degradation control of temperature is very important.

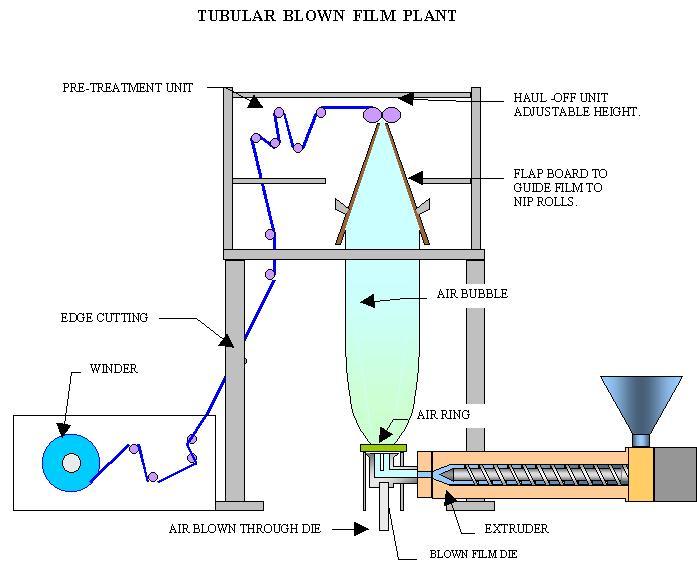

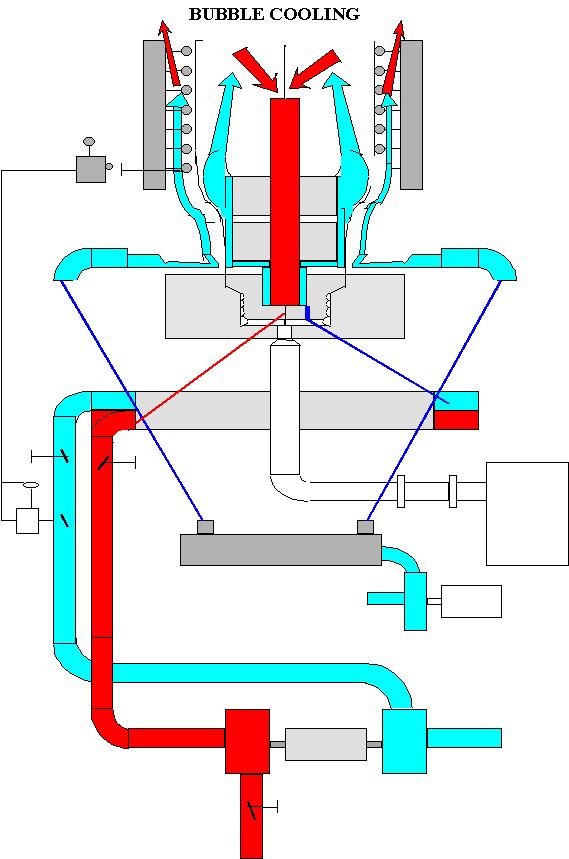

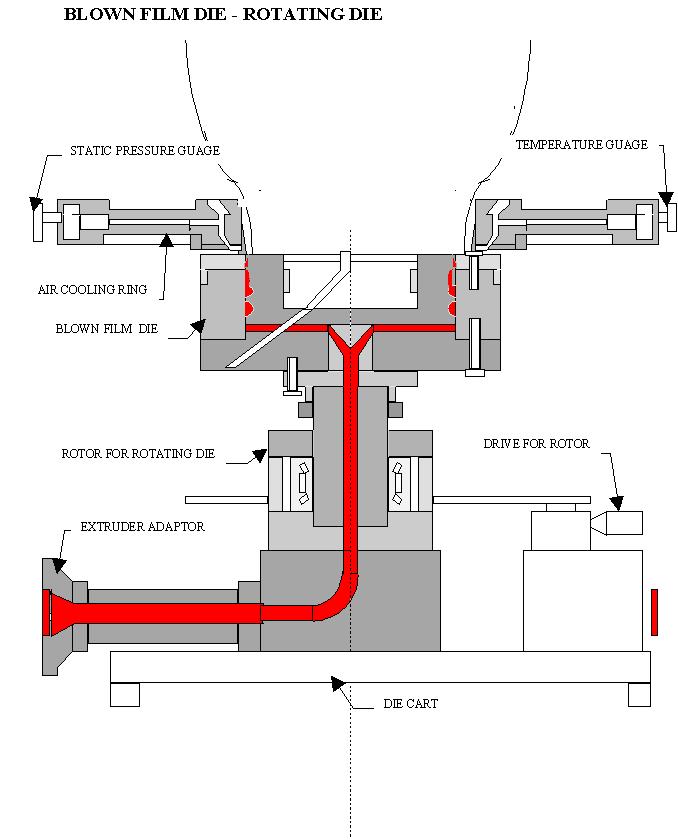

A large quantity of films is produced by extruding tube from a die in which the gap between the die ring and mandrel is small (0,635 mm or less). The thin tube is subsequently inflated and then cooled and flattened. Even thickness of the film is obtained by adjusting the die ring with respect to the mandrel. It is important in film extrusion that the melt flows out of the die at the same velocity all round the gap. This means that it is necessary to ensure that melt is delivered evenly to all parts of the die. A spiral mandrel is of use here. The melt flows from the adapter through a hole to a spiral channel around the mandrel. As the melt flows up the spiral, progressively more melt is able to escape from the spiral and flow by the annular gap between mandrel and die. Eventually all the melt is flowing up the annulus and on into a reservoir just behind the die land. the films with thickness more than 0.025cm is known as sheet.

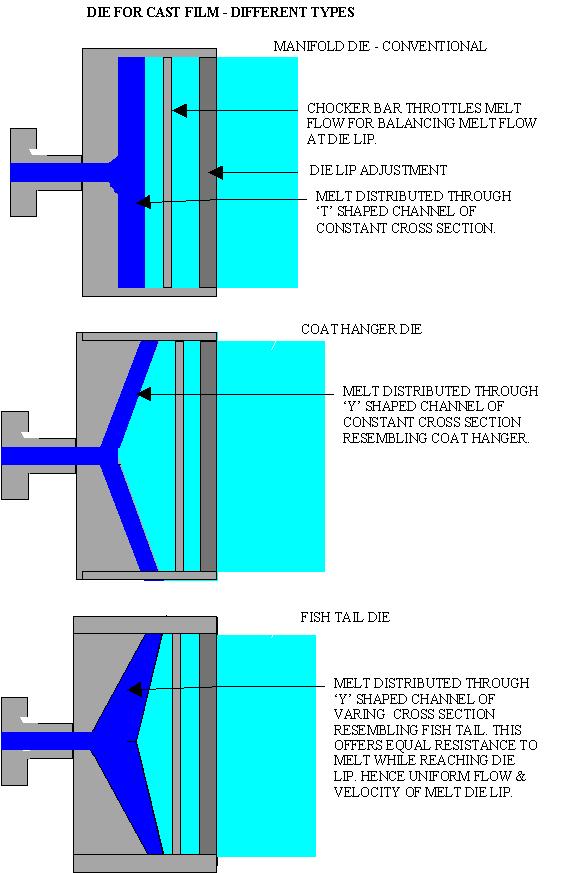

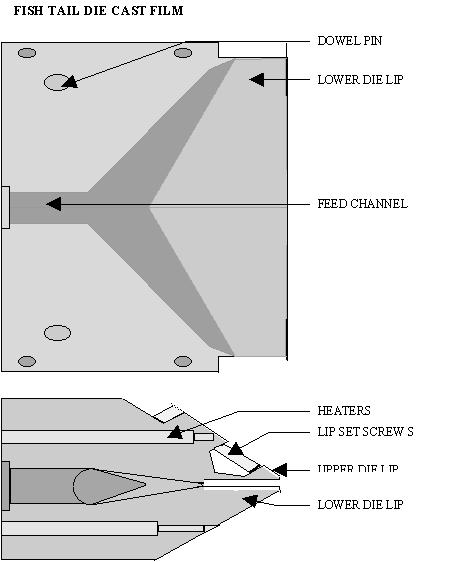

cast film die Melt from extruder is fed to the die centrlly. The entry to die has circular cross section which flares out in both directionsof die width to distribute the melt uniformly. The control of melt flow (by throttling melt flow) can be regulated by a choker bar. It is important that the molten polymer flows out of the die at a constant velocity and thickness all along the die lip. MANIFOLD DIE DESIGN The polymer is pumped from the extruder to the manifold (along channel down the length of the die) via a short inlet tube. The melt flows along the manifold and then past a restrictor bar and adjustable die lips out of the die. Because of a drop of pressure occurring in the melt in the manifold, as the distance increases from the inlet tube the flow rates from the die tend to be greatest near to the inlet tube. Feeding to the die center reduces, but does not eliminate, the different flow rates. It is therefore, common to fit an adjustable restrictor bar behind the die lips to throttle or otherwise adjust the flow of polymer to the die lips. Coat hanger design die For viscous melts, restricted bars alone are often insufficient to compensate for the pressure drop along the die. one way of reducing the problem is to bend the manifold so that the length of the die land is greater near the die inlet and tapering off towards the die ends. This arrangement is sometimes known as coat hanger die.

FISH TAIL DESIGN In a fish tail die land is longer in the die center and it gradually reduces towards both ends. The cross section of melt passage varies continuosly along the width of the die. The cross section resembles shape of fish tail. Fish tail dies are not desirable for making wide sheets for following reasons. (a) they are very bulky (b) very high clamping forces are required to hold the die halves together (c) the energy requirements to heat the larger surface of such dies becomes uneconomical prohibitive. PROCESSING PROBLEMS (1) Following materials are commonly extruded on commercial sale

(2) Some materials (like nylon) are hygroscopic i.e., they absorb moisture from the air. In an extruder this water turns to steam and the resulting extrudate contain bubbles formed by the steam causing the extrudate to expand as it emerges from the die. Therefore it is necessary to dry such material in an hot oven at suitable temperature before loading into the hopper. (3) Sometimes the bubbles caused by the steam becomes flattened during shear. These flattened bubbles tend to reflect light in transparent extrudates and appear like mica-flakes and are referred to mica marks. Other causes of such marks are entrapped air bubble, volatile liquids including plasticizers, monomer formed on degradation of polymer. (4) The amount of heat required to bring thermoplastic to its processing temperature will depend on

(5) Some thermoplastics are somewhat crystalline in nature. In order to melt the crystal latent heat will need to be supplied in addition to the heat required to raise the temperature. (6) Polymer melts differ enormously in their viscosity. In addition viscosity will vary with the rate of shear and the temperature of the melt. Screw speed controls the rate of shear. (7) Higher the melt viscosity higher the power consumption. (8) Some polymers are very fluid in the molten state. Extrudates from such materials tend to disturb unless they can be solidified very quickly. (9) It is found that the melt viscosity increases rapidly with increases in the molecular weight of the polymer. Hence, when there are problem handling fluid polymers it is often advisable to change to a higher molecular weight grade of polymer. (10) Polymer degrade on subjection to continual heating but some are more resistant than others. Among the important commercial thermoplastics PVC is probably the most succeptible to degradation since it is processed at temperature close to its decomposition temperature. Therefore, when extruding PVC very accurate temperature control will be necessary. (11) It is important that there are no places in the extruder or the die head (deep spots) where molten polymers can stagnate and decompose. (12) On emerging from the die of an extruder a thermoplastic material is in the molten state. Whilst cooling and hence getting it must be held in shape to prevent it distorting. (13) Section extrudate have been made from most thermoplastics. In general if the extrudate has a smooth but matte surface when a glossy finish is required, this indicates that the melt generally has been suitably heated by that the die temperature is too cold. Therefore increased gloss may often be obtained by increasing the die temperature. (14) Some extrudate may have a glossy finish but are lumpy and very irregular. This is usually the result of poor mixing of the melt. Good mixing is necessary temperatures and also subjected to different shear conditions and will thus have different viscosity . (15) The degree of mixing the melt in the barrel. This can be done by increasing the die land or fitting stronger screen packs. n The mesh should be finer other should be several layers of mesh. (16) Decreasing the melt temperature in the die will increase melt viscosity and increase the back pressure. Hence decreasing the die head temperature may help to reduce lumpiness. (17) Extrudates sometimes show bubbles and porosity. This is due to trapped gases. These can arise

(18) Blistering may be caused by water either absorbed into the granules or lying on the surface. The amount of steam produced to give blisters will depend on:

Hence polymers which are hygroscopic and /or require a high process temperature are normally carefully dried and stored in sealed tins. (19) The likelihood of depolymerisation causing blistering etc. can be reduced by using a flatter temperature profile along the barrel. (20) Extrudates sometime exhibit a surface irregularity characterised by a series of ridges perpendicular to the flow direction. This is known as sharkskin and is often barely visible to the naked eye but result in a form of mattness or lack of surface gloss. This critical extrusion rate appears to increase with increase kin temperature. Hence shark skin tends to be reduced with increase in temperature. (21) The Newtonian fluid the coefficient of viscosity i.e., the ratio of shear stress/ shear rate is constant. For many simple fluids like water the ratio shear stress/shear rate is constant. In other cases the ratio changes with increased shear. In general the ratio shear stress/shear rate is apparent viscosity. Therefore pseudoplastic materials become less viscous with increase in shear rate. Thermoplastic melts almost invariably show pseudoplastic behaviour. (22) Above some critical shear rate most thermoplastics exhibit a phenomenon variably known as elastic turbulence or melt fracture. It is characterised by various type of distortion which have a helical form . (23) Increase the melt temperature increases the critical shear rate for onset of melt fracture. The effect may therefore be reduced and perhaps even eliminated by reducing the shear rate and /or increasing the temperature. (24) The critical shear rate for onset of melt fracture is reduced by increasing molecular weight. There fore ,melt fracture is more likely to occur with high molecular weight grades than low molecular weight grade (25) The melt fracture effect can be reduced by

(26) The extruder may show black lumps or flecks. These may be due to polymer stagnate some points in the machine and decomposing. Pieces of decomposed material are then swept away by molten polymer at irregular intervals. The problems may be avoided by

The black particles may occur due to contaminated compound also. (27) It will be seen that by the time the last of the polymer is melting Air can only escape down a helical path through the granules back towards the hopper, if the rate of extrusion is greater, then the rate of back flow of air will be carried through into the extrudate resulting in porosity may therefore be reduced by reducing the rate of extrusion. (28) The back flow of air may be increased by increasing the die head pressure which can be done by lowering the head temperature. (29) Porosity usually most serious when feeding compound in power form as it is often done with rigid PVC compound . Hence the critical extrusion speed for onset of porosity is often lower with powder feed than with granulated compound. (30) When polymer melts pass round a spider leg and or through a breaker plate the molten material is separated. unless there is a high pressure on the side of the spider and /or breaker plate the separated melt will not fully knit together and lines or planes of weakness will occur. The head pressure may be increased by

(31) When extruding polymers, additives are sometimes deposited from the melt onto the forward part of the screw and onto the extruder head and die. This effect is know as plate- out and is most frequently met within PVC. Deposition occur s most frequently in regions of high temperature and high shear. Formulation also has an important influence. This can be educed by

A Guide to Injection Moulding of Plastics, Archieves of Articles by Prabodh C. Bolur, Useful Links , Author, Contact Author  if you are concerned with plastics molding, Order your copy NOW. |